Return to Start Page

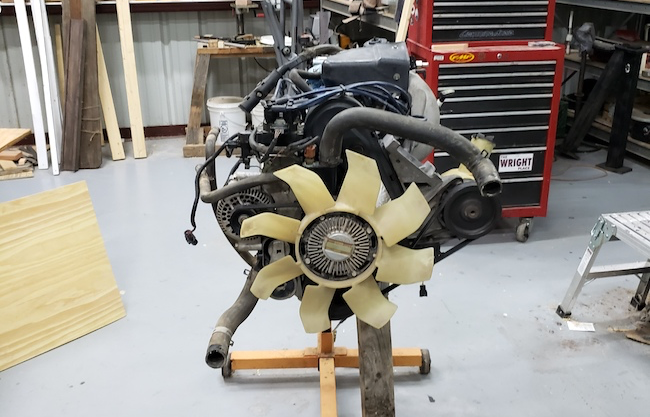

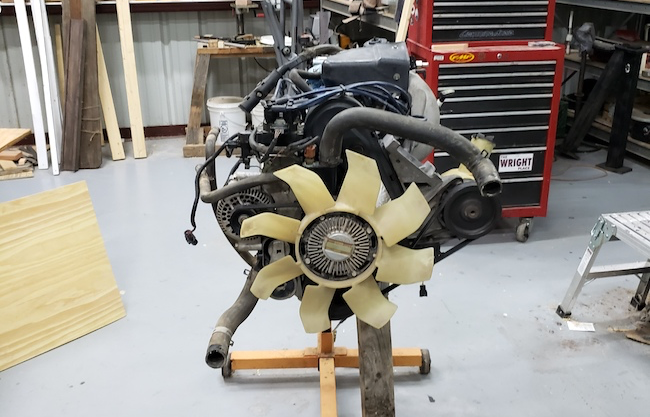

Here is a jeep update. So far, the new engine has been completely dissassembled and reassembled with new gaskets, bearings & rings. Some parts have been painted, and everything has been cleaned up. Some engine oil has been added and the oil pump has been primed. The spark plugs & wires were replaced and the engine wiring harness has been installed and it is now ready to go into the frame. Before it is ready for fitting up, the transmission and transfer case need to be mounted on the engine and the entire package will be located in the frame.

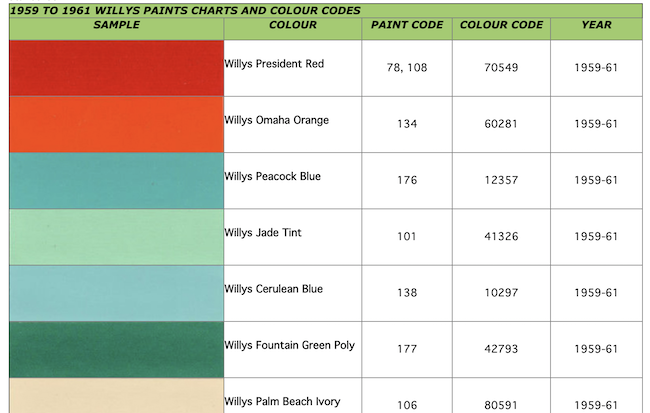

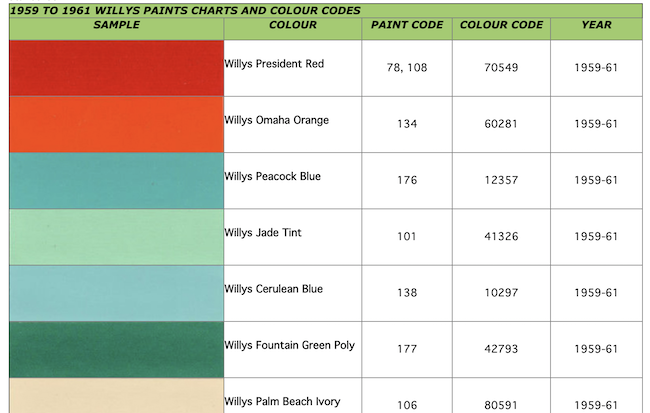

As I satarted to clean up the transmission, under the 1/8" of grime I found the original color once again. A quick search from historical Willys vehicles lists the color of Peacock blue as available starting in 1961 for the CJ-5. I am debating on obatining some of this color once again and when the case is ready for paint - paint it this color once again. I am not sure if the paint has faded over the years, because the color no listed as "Peacock Blue" is also pictured below."

The transmission was stuck in the present gear. The gears were stuck together to the point that after the engine was removed from the frame, we would use the transfer case as the break. We would push it around in nuetral, but when we wanted to keep it stationary, we simply shifted the transfer case from nuetral to any gear (either 4 wheel drive or 2 wheel drive) and the transmission was stuck enough to lock up the tires when rolling. After removing the top it was clear as to why. The lower gear train was completly obscured. After talking to Wyatt, we followed his advise and filled up the tarnsmission case with diesel fuel to act as a solvent/lubracant and allow the items to move again.

The filling it up, consisted of placing it on the tail gate and having Ethen & Kyle hold it as we went down to the fuel station. We filled it up, and noticed all of the common holes that pass lubrication between the transmission and the transfer case. We decided to go into the store and obtain some Hubba Bubba Max chewing gum. We all softened up some pieces and plugged the holes. Then Ethen & Kyle held it stationay as we drove home. This worked wonderfullly, but the bearing still allowed fluid to leak out and I had two less than impressed teenagers when we arried home.

After letting the transmission sit in this condition for a week, we removed the fluid and pulled it completely apart. What we discovered was there was over 1" of sludge in the bottom of the case and the gears that were submerged were disolving in the rust from the last 30 years. The design of this transmission is the shift lever comes in the top of the case. When the protective boot wore away, any rain that landed on the shift lever had a straight path to the internals of the case. The oil was probably floated out and the water remained to eat away the teeth. I was eventually able to get the shift levers freed up (although not very smoothly), but the gears are not going to be salvagable.

This gear stack is the lower ideler shaft. It is all machined out of one piece. Luckily all of the internal pieces for this T90 transmission are comercially available and incluced in the "Major rebuild kit". It looks like I will need to go that route. Dad mentioned this transmission had difficulty going into reverse, and I cannot point to a root casue, but it would probably have a difficult time maintaining any speeds in any gears if we used these gears.

Return to Start Page

| Here is a jeep update. So far, the new engine has been completely dissassembled and reassembled with new gaskets, bearings & rings. Some parts have been painted, and everything has been cleaned up. Some engine oil has been added and the oil pump has been primed. The spark plugs & wires were replaced and the engine wiring harness has been installed and it is now ready to go into the frame. Before it is ready for fitting up, the transmission and transfer case need to be mounted on the engine and the entire package will be located in the frame. |

|

|

|

|

As I satarted to clean up the transmission, under the 1/8" of grime I found the original color once again. A quick search from historical Willys vehicles lists the color of Peacock blue as available starting in 1961 for the CJ-5. I am debating on obatining some of this color once again and when the case is ready for paint - paint it this color once again. I am not sure if the paint has faded over the years, because the color no listed as "Peacock Blue" is also pictured below."

|

|

|

| The transmission was stuck in the present gear. The gears were stuck together to the point that after the engine was removed from the frame, we would use the transfer case as the break. We would push it around in nuetral, but when we wanted to keep it stationary, we simply shifted the transfer case from nuetral to any gear (either 4 wheel drive or 2 wheel drive) and the transmission was stuck enough to lock up the tires when rolling. After removing the top it was clear as to why. The lower gear train was completly obscured. After talking to Wyatt, we followed his advise and filled up the tarnsmission case with diesel fuel to act as a solvent/lubracant and allow the items to move again. The filling it up, consisted of placing it on the tail gate and having Ethen & Kyle hold it as we went down to the fuel station. We filled it up, and noticed all of the common holes that pass lubrication between the transmission and the transfer case. We decided to go into the store and obtain some Hubba Bubba Max chewing gum. We all softened up some pieces and plugged the holes. Then Ethen & Kyle held it stationay as we drove home. This worked wonderfullly, but the bearing still allowed fluid to leak out and I had two less than impressed teenagers when we arried home. |

|

|

|

|

After letting the transmission sit in this condition for a week, we removed the fluid and pulled it completely apart. What we discovered was there was over 1" of sludge in the bottom of the case and the gears that were submerged were disolving in the rust from the last 30 years. The design of this transmission is the shift lever comes in the top of the case. When the protective boot wore away, any rain that landed on the shift lever had a straight path to the internals of the case. The oil was probably floated out and the water remained to eat away the teeth. I was eventually able to get the shift levers freed up (although not very smoothly), but the gears are not going to be salvagable. | |

| This gear stack is the lower ideler shaft. It is all machined out of one piece. Luckily all of the internal pieces for this T90 transmission are comercially available and incluced in the "Major rebuild kit". It looks like I will need to go that route. Dad mentioned this transmission had difficulty going into reverse, and I cannot point to a root casue, but it would probably have a difficult time maintaining any speeds in any gears if we used these gears. |

|

Return to Start Page