| It seems to me that I have talked to many people who have many interesting stories to tell, but every time I check the web site there are no stories for me to sit back and enjoy. I know that Mia, Sabrina, and AJ all have one, but still I sit here reading my own over and over, so here goes another one for me to read as well.

As most of you know, my white car has taken ill and is on an extended leave from work. I have tried my best to do without my little friend, including finding another substitute to drive back and forth to work, but I keep missing the Mazda, so I decided that this Saturday I would see if I could help it back on its feet. |

|

|

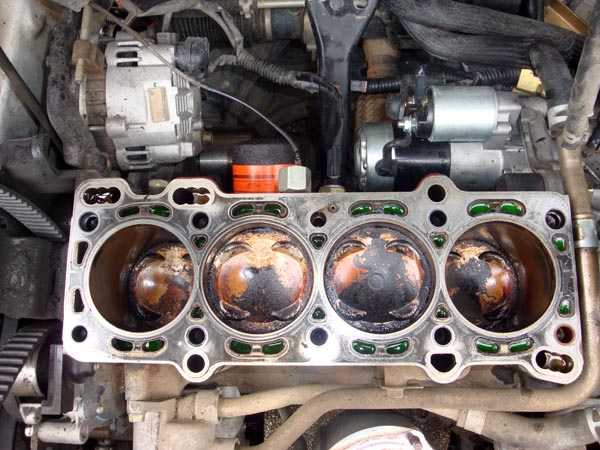

As it turns out, today was the first day that all three of the components needed to make such a repair came together... free time, no rain, and daylight. For some reason, these three have been hard to come by at the same time since moving here. I started to rip out the engine and got quite far on my task before I was able to ascertain whether or not there was anything salvageable in the Mazda. As it turns out from looking at this and the next photos, the pistons and the valves didn't get too friendly when the timing belt gave up the ghost. I was very relived to find this information out. This means that a new head gasket and timing chain and we are once again in business. |

| There is some carbon fouling (of course) but that can be cleaned off and then put back together. Taking apart the engine was no where near as difficult as I kept imagining it to be. Before I started this project I found some gloves that I could wear. The weather was overcast, but no rain. The high was a balmy 44 degrees, and I thought that a pair of gloves might just help out. As it turns out, the gloves made all the difference in the world. I have never been a fan of gloves (because you can't feel the bolts your are trying to play with) but it makes for a very comfortable day. What I mean is that even though it was cold, the tools weren't cold. |  |

|

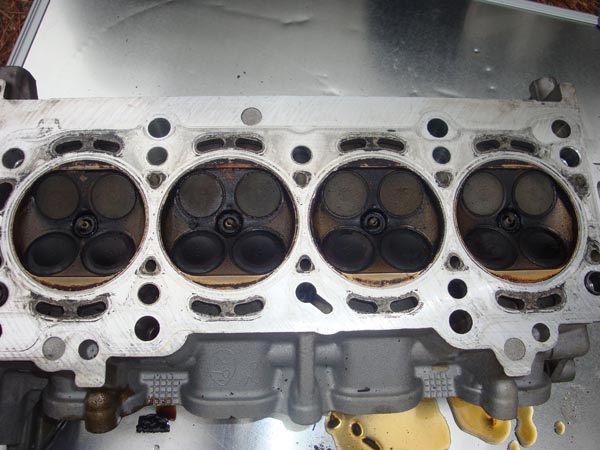

This may sound trivial, but when your fingers get cold it is hard to make them do the detailed work that is necessary if the loosening of bolts. Of course the sweat shirt and thermal underware helped out considerably. Once I had the head off and determined that everything looked good and the vehicle was indeed salvageable, then I started to disassemble the timing belt. From the top of the engine it looked just fine (as pictured above by the pistons) but something just didn't add up. It failed (and only after 16 months and 35,000 miles) and I wanted to know why. After pulling off the valve cover I could see that the belt had walked toward the outside of the engine and was rubbing on |

| the plastic timing belt cover/guard. Terra kept saying that she could smell burning plastic or rubber, but I never could. Maybe she was correct and could smell the melting that was taking place under the hood. The belt had melted grooves into the guard/cover and in some places right through it. I couldn't figure out why the belt would walk toward the outside of the engine, but one thing kept haunting me. |

|

|

The noise that I kept hearing (you remember the mysterious noise that I kept saying sounded like a bearing - but was told it was the throw out bearing...) was still unaccounted for. If you look in the previous photo you can see that there are some circular burns into the timing belt cover. After pulling off both the idler pulley and the tensioner pulley, I found that the bearing on the tensioner pulley had completely failed. The pulley started to come apart and when it did, the slack in the timing belt allowed the crank shaft to spin in the teeth of the timing belt. |

| This spinning in the teeth caused the teeth to give way under the increased load. That is what caused the engine to come out of time and stop working. What this means is when I put this beast back together there will no longer be any mysterious bearing threatening to go out, it also means that hopefully the car will once again be able to run better than before. I still don't understand why these bearings went out so soon. When I replaced the timing belt I also replaced the idler pulley as well as the tensioner pulley. |

|

|

When I replace it this time, I will go ahead and replace the tensioner and idler once again. The good thing about pulling this apart was that when I went to pull off the crank shaft pulley (harmonic balancer) I didn't need to use any gear pullers because the last time when I assembled this contraption (in the rain I might add) I put never seize on the interior of the pulley and it came off just like it was waiting for me to pull it off. Due to the fact that I live in a thriving metropolis, all of the parts that I need to put this back together once again are on order and should be in on Tuesday, so hopefully if the rain cooperates, I will be driving this car to church next week. |

| The only problem that I have with the re-assembly of this project is that I had to pull off about 25 electrical connectors. Anyone who has ever messed with those blasted connectors knows that they break when taking them apart. Of the 25 I only broke 1 so that one will have to be repaired - but that is minor.

At least the kids were entertained inside while I was dissecting the car. Once it got close to dark I packed up all the tools and put them up as well as fill the trunk with the engine components - to keep them from walking off between now and when I have need of them once more... |

|